Clean and abundant water nurtured the fish and metal processing industry.

More than 2,000 prototype parts

The Jet Stream series has been designed and manufactured quite a few times due to its unprecedented mechanism and shape. There are more than 2,000 prototype parts. Investments in terms of funds are natural, but investments in terms of time and labor have also taken a considerable amount of time to commercialize.

It’s a casual small part, but it’s packed with the world’s best Japanese cutting-edge technology.

The parts used in various places such as bearings are not made overseas, but are composed of the world’s highest level parts that can only be manufactured with Japanese technology.

It doesn’t look that much, but because the number of parts per reel is large (the number of parts is comparable to the mid-sized spinning reels of major manufacturers), the time to complete is compared to making a normal fly reel. Will be significantly different. Even if the number of parts is three times that of a normal reel, if you simply say that the time is three times as long, that is not the case.

Production time is 4 to 5 times

It takes 4 to 5 times longer than a normal fly reel. In order to process at a turning center and a machining center, you must first cut out the material. If the number of parts is large, the cutting time will increase accordingly. In addition to that, there are decisive differences in the manufacturing process compared to general fly reels. It is the number of dimensional accuracy controls. All design and manufacturing are done at our factory.

Dimensions deviate from the standard …? What is

To explain in a little more detail, no matter how high-performance NC machines are, if you are cutting many products, the dimensions will always shift little by little due to the influence of tool cutting edge wear. Moreover, when it comes to dimensional accuracy in units of 1/1000 mm, if the facets get entangled even a little, it is easy to make only one thing that deviates from the standard. While managing and adjusting the deviation and non-standard items, we will cut the product to fit the dimensions within the standard. Since a general reel has a large standard width of dimensions and only one or two measurement control points, it can be manufactured in large quantities in a short time with little effort. This is a decisive difference from general reels in terms of production control (and cost). Let it go by machine … Please understand that such a manufacturing method is not allowed in Jetstream. (It’s a part that you don’t understand at all)

A group of parts that require stricter dimensional control than the bearing part … Why should it be so strict …

The reason is the ultra-high speed winding mechanism of the jet stream. The high-speed take-up mechanism consists of a number of folded parts, from the vertical front drag (when the reel is laid down) to the recoil thruster cap. Suppose the dimensions of each part differ by, for example, 0.01 mm. If there are 10 parts with different dimensions and 10 of them are stacked (actually, 10 or more parts overlap), the difference will be 0.1 mm. If this is manufactured with a dimensional tolerance of ± 0.02 mm, a deviation of up to 0.2 mm will occur.

In addition, dimensional changes due to anodizing are also added.

Anodizing treatment (anodizing treatment) is a treatment that impregnates metal with color to increase the surface hardness, but when processing, parts are hung vertically like dried persimmons and soaked in sulfuric acid etc. Even if the upper item and the bottom item have the same dimensions before being soaked, the dimensions will change slightly after being soaked. It depends on the part, but it may be up to 0.002mm to 0.004mm and 0.010mm to 0.040mm. (If the color condition is not good and you want to redo the process, you have to consider it.)

Management in units of one-thousandth mm, which is not allowed in one-hundredth mm

Since it is necessary to consider the dimensional change in the anodizing process (anodizing process), if the dimensional control is performed in units of 1/100 mm, when assembled, it is easy to make a substitute with a difference of about 0.5 mm in total. It is.

If it is different so far, it will be a substitute that can not be said that the product is made with high accuracy. It is a numerical value that actually causes a problem in terms of function if it deviates by 0.5 mm.

We are particular about dimensional control at the micron level

(By the factory standard, ± 0.004 mm is rejected as non-standard. The acceptance standard is within ± 0.002 mm, but the standard is set to 0.000 mm. Even if the dimensions differ by 0.002 mm in 10 places, 0.02 mm It will be an error of.)

As described above, stricter dimensional tolerances are required than the bearing part, and it is necessary to manage them one by one, so it is literally an order of magnitude difference (1/100 to 1/1000). Is hanging.

Number of processing steps and hardening treatment

The processing process of the turning center and the machining center also requires about 150 steps of turning and cutting to make one reel only by processing metal. For parts other than metal, we also perform processing such as resin molding and laser processing. Since the number of parts is large, the metal hardening treatment and alumite treatment after processing also cost a considerable amount of money. In recent years, a well-known famous manufacturer has outsourced production to countries with low labor costs in China and Asia in order to reduce costs, but Toyo Kogyo does not outsource production overseas. I would like to realize cost reduction by the method and leave Made in Japan to the last. Moreover, we have a policy of manufacturing and delivering products to everyone with a focus on Made in Toyama Japan (our factory is located in Toyama Prefecture).

MADE IN Toyama JAPAN With the soul … Environment blessed with tackle test … Toyama

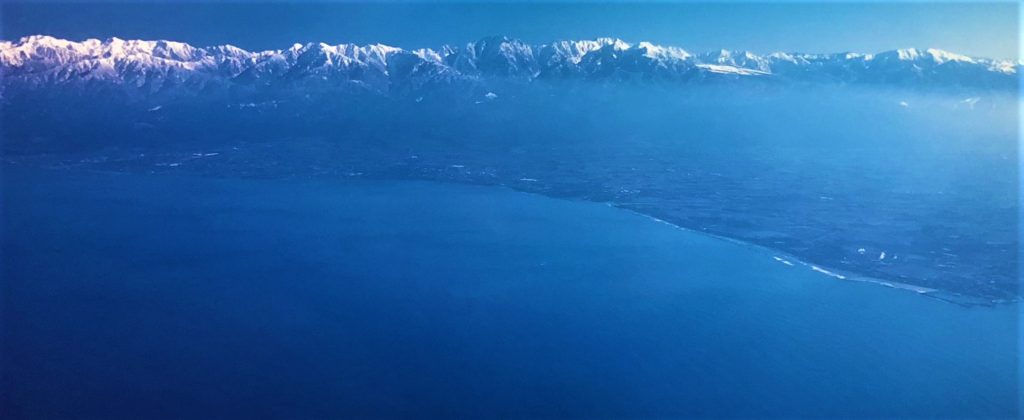

3000m-class mountains and Toyama Bay, which is known as a natural cage

Toyama Bay has been selected as the most beautiful bay club in the world. (In Japan, two bays, Matsushima Bay and Toyama Bay in Miyagi Prefecture, have been selected.)

All fish species, whether freshwater or seawater, live within 20 minutes of the factory.

As shown in the photo above, Toyama Prefecture has a seabed from mountains at an altitude of 3,000 m to a depth of 1,000 m.

The terrain with a height difference of 4,000 m in a very short horizontal distance is rare in the world, and many people such as academic researchers from overseas are visiting for research. If you pay attention to the fact that the altitude difference is blessed with fishing, it is possible to catch char, yamame trout, rainbow trout, black bass, and dolphin fish in one day.

Also, even in the midsummer of August, the water temperature of the mainstream river, which is not so high, is so low that you cannot enter the river for a long time even if you wear waders. This point is also a good environment for mountain fish.

You can reach an altitude of 1,000m or more within a few tens of minutes by car from the plains, so it feels like Hokkaido is right there.

We are blessed not only in the field but also in the manufacturing environment

Why Made in Toyama Japan? What is the famous industry in Toyama prefecture? I think that there are many answers that the medicine is the first when asked. The image of Toyama as a medicine is too strong, so even local Toyama residents are not well known, but in fact Toyama Prefecture has been the number one metal kingdom in Japan for more than 10 years in a row. .. It is no exaggeration to say that aluminum is the best in the world as well as Japan as the area where various metal processing companies are concentrated. Therefore, there are many excellent companies.

Blessed manufacturing environment (All processing is done at our factory and cooperating factories in Toyama prefecture.)

As just one example, in terms of familiar products, NC machines that carve out the heart of automobiles such as engines, missions, and crankshafts of major automobile manufacturers in the world, and production lines are actually made in Toyama Prefecture. We have assembled a production line (manufacturing and arranging all kinds of NC machines for metal processing over several hundred meters) at the Toyama factory, and after confirming the operation as a line, we deliver it to factories all over the world. We provide the entire production line to Toyota, GM, and many other major automobile manufacturers in Japan and overseas (which boast an overwhelming share in the world).

The engine made by Toyota cars running in Japan is 100% cut by NC machines manufactured by companies in Toyama prefecture from Prius to Crown (all models). Since NC machines directly cut the engine, they are also involved in engine design.

There are many companies full of creativity

To give an example, it is a different company from the above, but Honda’s VTEC engine (variable valve timing and lift mechanism) was also developed by a company in Toyama prefecture. In recent years, demand for manufacturing hybrid vehicle motors has been increasing. In addition, there are companies that have the largest share of F-1 wheels in the world casually, and there are several companies that provide NC machines (manufacturers of machine tools for metal cutting) to Boeing, other than automobile-related companies. And, thanks to the many other great companies, there are countless companies related to them. Toyama Prefecture has all the environment for metal processing manufacturing in the prefecture.

Introducing a small part of MADE IN Toyama manufactured in Toyama, the kingdom of metals that boasts the best in Japan

If there is something that is easy to see and familiar to everyone, it supports Japan and the world economy from below.

4 out of 5 companies below manufacture and sell NC machines such as machining centers.

Komatsu NTC, YKK, Sugino Machine, Nachi-Fujikoshi (NACHI), Kitamura Machinery

Komatsu NTC

NIPPEI TOYAMA corporation

It is a great company that supplies the entire production line that manufactures engines, missions, crankshafts, etc. to major automobile manufacturers around the world. The factory itself is huge because it manufactures production lines. The engine (gasoline) of all Toyota cars running in Japan is machined by NC machine made by Nihira Toyama.

https://ntc.komatsu/en/

YKK

YKK is a world leader in aluminum sashes and fasteners. Aluminum products require a lot of electricity anyway. We manufacture a huge amount of aluminum products with good quality water resources.

The observation corridor and observation deck of Tokyo Sky Tree are made by YKK.

https://www.ykk.com/english/

Sugino Machine

Companies with a wide range of unique technologies such as high-pressure pumps, water jets, and machine tools. Due to the development of equipment that operates at nuclear power plants, the building-shaped office building, which is rarely seen as a factory, is also characteristic.

https://www.sugino.com/index-e.html

Nachi Fujikoshi

Manufacture of cutting tools, materials, robots, bearings, etc. It is also famous for manufacturing axle bearings for Shinkansen and railways. Tokyo Metro’s subway axle bearings have a 100% share.

http://www.nachi-fujikoshi.co.jp/eng/index.html

Kitamura Machinery

It is famous for manufacturing high-precision and high-rigidity machining centers, including more than 300 patents in 24 countries around the world and the award of Best Machine Tool Maker in the United States. Supply tens of thousands of machine tools to the aircraft industry in North America and the automobile industry in Europe (Boeing, Mercedes-Benz).

https://www.kitamura-machinery.com/

Toyama Prefecture has all kinds of metal processing, from ultra-high tech like the above companies to traditional traditional techniques.

Why are so many metal processing industries concentrated in such a countryside? … I think you will have questions.

The reason is … water resources. The Tateyama mountain range in Toyama Prefecture stores snow during the winter and brings abundant meltwater from spring to summer.