Shaped by pristine water—and a culture of precision.

More than 2,000 prototype parts were made to bring the JET STREAM series to life.

With no precedent to follow, we set out to design an entirely new mechanism and form—repeating the cycle of engineering, machining, testing, and refinement again and again.

Yes, the financial investment has been significant.

But what truly tells the story behind this reel is the years of time, labor, and iteration required to make it real.

What may look like ordinary components are built to a level of accuracy that defines Japanese manufacturing.

Every critical part—especially the bearings—comes from Japan, supported by a supply chain and process control that are not easily replicated elsewhere.

Though the reel appears compact, it contains a remarkable number of components—comparable to the internal complexity of many mid-range spinning reels from major manufacturers.

As a result, producing a single JET STREAM reel doesn’t take two or three times the effort of a standard fly reel—it takes four to five times more.

Even with CNC lathes and machining centers, every component begins with cutting raw stock and preparing blanks.

The more parts a reel contains, the more that foundational work multiplies.

And above all, what sets us apart is dimensional accuracy—far beyond what is typical in fly reel manufacturing.

Design, machining, finishing, and QC are all performed in-house, at our own factory.

When even a micron matters — precision in every cut

Even the most advanced CNC machines experience microscopic drift over time. Tool wear measured in mere thousandths of a millimeter can shift dimensions—especially in manufacturing as intricate as JET STREAM. A single speck of swarf or a minute built-up edge on a cutting tool can push a component out of spec, sometimes by as little as 0.001 mm.

This is where our craft takes over.

We continuously monitor production and make manual adjustments to bring parts back within tolerance—because we know precision matters, even when it’s invisible to the naked eye.

Where mass-produced reels typically require only one or two critical checks, we inspect dozens of dimensions.

That difference is exactly why most reels can be produced quickly and inexpensively—while JET STREAM demands time, attention, and discipline.

There is no room here for “set it and forget it” manufacturing.

Tighter than bearing-seat tolerances — why go that far?

The answer lies in our Recoil Thruster System, designed for ultra-fast line retrieval.

This mechanism stacks multiple components vertically—from the front drag through to the thruster cap—forming a precision-critical column.

If each stacked part were off by only 0.01 mm, a ten-part assembly could drift by 0.1 mm.

With a typical tolerance of ±0.02 mm, total deviation could exceed 0.2 mm—enough to compromise performance.

And then there is anodizing.

Anodizing doesn’t only add color and surface hardness—it can also influence dimensions.

Parts are fixtured and immersed in a sulfuric-acid bath, and even when two components start out identical, slight variations in position, exposure, and current density can produce dimensional differences after treatment—often around 0.002–0.004 mm, and in some cases as much as 0.010–0.040 mm.

When your system tolerances live in thousandths of a millimeter, those changes matter—and they accumulate.

Our standard: ±0.002 mm — and we aim for zero

Our internal QC rejects anything beyond ±0.004 mm.

Our goal is simple: to approach 0.000 mm deviation as closely as humanly possible.

Even if ten components each deviate by only 0.002 mm, the cumulative total is 0.02 mm—still within our standard.

These tolerances are tighter than those typically applied even to bearing seats, which is why producing JET STREAM requires an entirely different league of precision.

The difference isn’t just something you can feel.

It’s something you can measure.

Made in Toyama, Japan — by choice

While many well-known brands have moved production to lower-cost countries in Asia, we chose a different path.

At Toyo Industry (TOYO REELS), we keep every stage of production in Japan—not only to preserve craftsmanship, but to push it forward.

We manufacture in Toyama, a region defined by crystal-clear water and a long tradition of metalworking.

Our goal is not simply to reduce costs.

It is to prove that micron-level precision and Made in Japan quality still belong in the modern world.

MADE IN TOYAMA, JAPAN

With heart, with rigor — a land made for tackle testing

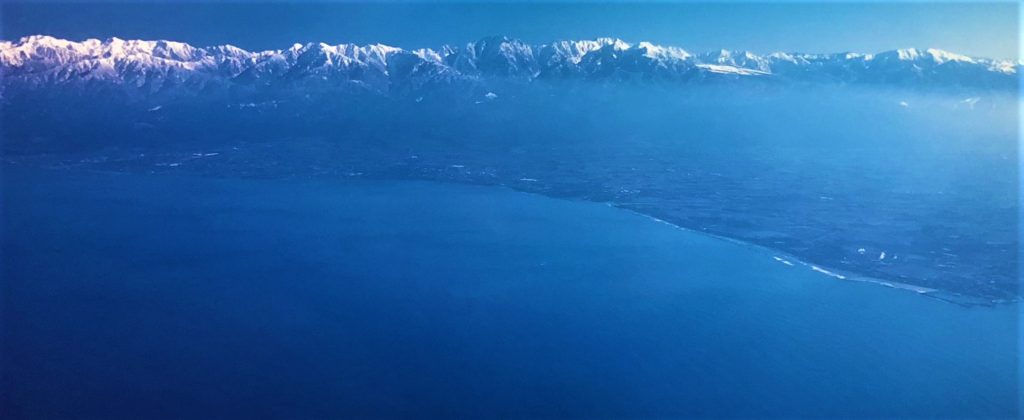

Framed by 3,000-meter peaks and deep, nutrient-rich waters, Toyama is a natural proving ground for tackle.

Toyama Bay has been recognized by the Most Beautiful Bays in the World Club.

(In Japan, only Matsushima Bay in Miyagi and Toyama Bay have received this recognition.)

A Rare Geography for Diverse Fishing — Just Minutes from Our Factory

Within a 20-minute drive from our factory, you can access an extraordinary range of fishing environments—both freshwater and saltwater.

Toyama Prefecture is defined by a geographical formation found in very few places on Earth:

towering 3,000-meter alpine peaks that plunge directly into the sea, reaching an ocean floor more than 1,000 meters deep, all within an exceptionally short horizontal distance.

This creates a vertical drop of nearly 4,000 meters from mountain summit to seabed.

Because of this unique terrain, Toyama has drawn the attention of academic researchers from around the world.

From an angler’s perspective, it is equally remarkable.

In a single day, it is realistically possible to fish for char, yamame, rainbow trout, black bass, and even dorado—a diversity rarely found in one region.

Even during the peak of summer, rivers fed by alpine snowmelt remain strikingly cold. Extended wading requires care, but these low water temperatures create an ideal, stable habitat for trout throughout the season.

In Toyama, you can drive from lowland plains to elevations above 1,000 meters in under an hour.

The climate and conditions change so dramatically that it feels as though a northern wilderness lies just beyond the city—an environment uniquely suited for testing fishing tackle in the real world.

A Manufacturing Paradise — Why We Stay in Toyama

When people think of Toyama, many associate it with medicine.

But fewer—locals included—realize that Toyama is also one of Japan’s most concentrated centers of metalworking, with a deep industrial history and a culture built around precision manufacturing.

Toyama’s reputation extends well beyond Japan.

In aluminum machining and processing in particular, the region has earned recognition for its technical depth and manufacturing capability. The result is a rare ecosystem: world-class suppliers, specialized expertise, and advanced production infrastructure—densely clustered in one place.

That concentration is exactly why we choose to stay here.

World-Class Manufacturing, Right Here in Toyama

Every JET STREAM reel is produced through our own in-house processes and, where needed, in close collaboration with trusted partners within Toyama Prefecture—partners we know, visit, and work with directly.

Below are a few of the key specialists who support this “Metal Kingdom,” and help make JET STREAM possible.

Toyama is also home to numerous globally recognized manufacturers across a wide range of industries.

Komatsu NTC

A leading supplier of complete engine production lines to major automakers worldwide, including Toyota and General Motors.

In Japan, gasoline engines for Toyota vehicles are machined using Komatsu NTC equipment.

YKK

A global leader in aluminum architectural systems and fasteners.

YKK utilizes Toyama’s abundant, high-quality water resources to produce large volumes of aluminum products.

Their aluminum components are also used in the observation decks of the Tokyo Skytree.

Sugino Machine

Specializes in high-pressure pumps, water-jet systems, and nuclear-grade precision machining equipment.

Their headquarters factory is designed in a high-rise form, symbolizing a focus on advanced research and development.

Nachi Fujikoshi

Manufactures cutting tools, industrial robots, bearings, and specialty materials.

Supplies axle bearings for Tokyo Metro’s subway trains, supporting one of the world’s busiest urban rail networks.

Kitamura Machinery

Holds more than 300 global patents and has received major industry awards in the United States.

Supplies ultra-precision machining centers to the aerospace and automotive industries, including manufacturers such as Boeing and Mercedes-Benz.

Why So Many Factories in a Rural Region?

In a word: water.

The Tateyama mountain range accumulates heavy snowfall in winter and releases it as pure meltwater through spring and summer. This natural water resource enabled the early development of hydroelectric power in Toyama, and even today Hokuriku Electric Power Company is known for some of the most competitive electricity rates in Japan.

Industries that depend on both large amounts of electricity and high-purity water—such as aluminum refining and semiconductor production—have naturally flourished here.

Toyama is also home to:

- Kurobe Dam, Japan’s largest dam

- Shōmyō Falls, Japan’s tallest waterfall

This region is truly a kingdom of water—and of metal.

A Skilled, Stable Workforce

Toyama also benefits from a strong and resilient workforce:

- #1 in Japan for average home floor space

- #2 in homeownership

- #4 in dual-income households

- #2 in household income

These conditions support a workforce that is rooted in the region, reliable over the long term, and highly motivated—another reason we can confidently continue to deliver products proudly labeled MADE IN TOYAMA, JAPAN to the world.

Toyama is a land of mountains.

True to its name, those peaks gather snow in winter, the snow becomes water, and that water sustains both the fish in our rivers and the metalworking industry that defines this region.

Perhaps it is no coincidence that JET STREAM was born from this very landscape.